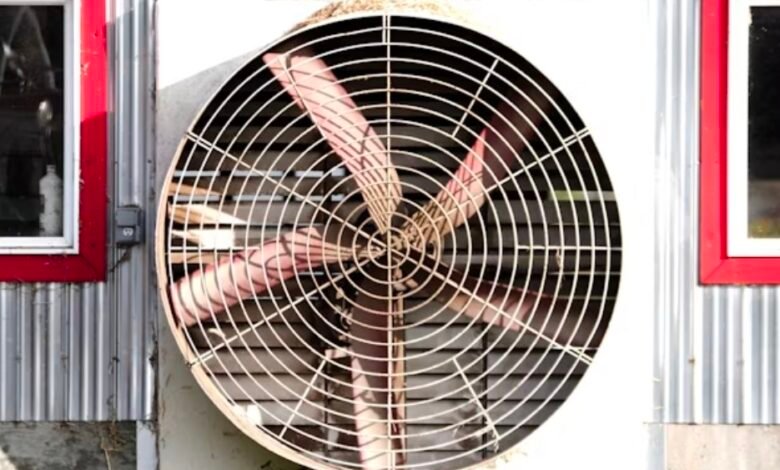

Key Factors to Think About When Picking an AC Fan for Sale for Your System

For industrial and commercial operators, choosing the right AC fan for sale is important. Your choice can affect airflow efficiency, energy costs, the fan’s reliability over time, and the operational lifespan of the system. For harsh industrial settings exposed to dust, water, or other contaminants, an IP65 fan guarantees protection and helps with consistent performance and minimal maintenance. In this article, we discuss the most important things AC fans for sale, focusing on performance, environmental resilience, energy efficiency, and reliable performance over time.

AC Fans and Their Uses in Industries

AC fans are utilized in industrial, commercial, and HVAC systems for the movement of air. AC fans come in different configurations such as axial and radial (centrifugal) fans, each with specific advantages.

- Axial AC fans – Operate by pulling and pushing air parallel to the fan axis, providing high airflow in low resistance settings such as cooling towers or large pieces of machinery.

- Radial AC fans – Operate by pulling and pushing air at right angles to the fan axis and are able to provide higher static pressure. They are suited for use in ducted systems, filtration units, or other systems with intricate airflow paths.

When buying an AC fan for sale, the application of the fan, airflow, and system resistance must be considered. For such places with moisture or dust, using an IP65 fan increases the fan and equipment lifespan by protecting from dust ingress and low-pressure water jets.

Key Performance Metrics to Evaluate

For B2B buyers to purchase the most suitable AC fan, certain performance metrics must be evaluated such as:

- Airflow Capacity (CFM or m³/h): Measures the volume of air the fan can move. Correct airflow must be supplied for environment control and cooling efficiency.

- Static Pressure (Pa): Measures a fan’s ability to overcome system resistance from ducts, filters, or enclosures. For applications with narrow or restrictive pathways, high-pressure fans are a must.

- Fan Speed (RPM): Higher speeds contribute to too much airflow and can also inefficiently consume too much energy and/or create too much noise.

- Power Consumption: Energy costs can be saved with the use of efficient motors, especially in systems with multiple fans in continuous operation.

- Noise Levels: In office-adjacent or personnel dense industrial areas, noise is of concern.

By ensuring performance parameters are met, reliability can be achieved with an IP65 fan even in water and dust exposed environments while ensuring efficiency and durability.

Environmental and Safety Considerations

There are numerous potential risks in an industrial or commercial setting, such as dust, moisture, exposure to chemicals, and extreme temperatures. Selecting an environmentally compliant fan can ensure operational safety as well as increase the fan’s life expectancy:

- Ingress Protection (IP Rating): These IP65 fans are dust tight and guarded against water jets, making these fans suitable for harsh industrial, outdoor, or process-heavy applications.

- Operating Temperature Range: It is important the fan can handle ambient or equipment heat, particularly in high temperature processes.

- Corrosion Resistance: Some fans are made with strong materials which can withstand chemical or humid environments without deteriorating.

- Compliance with Safety Standards: Safety rated fans can be effective in maintaining industrial regulations and workplace safety.

Meeting the environmental factors helps B2B operators lower maintenance needs, avoid unplanned equipment failures, and ensure the safety and productivity of the workers.

Energy Efficiency and Control Options

Energy efficiency is an important factor for industrial buyers. Operational expense can be reduced with the use of optimized fans as they lower electricity consumption while maintaining static pressure and high airflow.

- High-Efficiency Motors: Operational expenses can be reduced via AC fans with optimally designed electrical motors as they generate maximum airflow per watt.

This also applies in cases of multiple fans in large operation scales or continuous ventilation needs.* Variable Speed Control: Adjustable fans streamline airflow to real-time requirements, conserving energy during low-demand periods.

- Integration with Automation Systems: It is possible to integrate fans with building management systems or process control systems so their operation is adjusted based on temperature, pressure, or other relevant environmental sensors.

- Sustainability: Efficient fans used within air conditioning systems reduce energy consumption, ease the load on motors, and contribute to sustainability efforts.

Selecting an IP65 fan with high energy efficiency ensures reliable functioning in extreme conditions and enhances cost-effectiveness and environmental sustainability.

Maintenance, Longevity, and Reliability

Reliability is the most important factor for fans used in industrial settings. Fan downtime or failure is likely to cause or exacerbate interruptions to business operations:

- Durable Construction: Fans produced from corrosion resistant metals or other reinforced materials suffer from less temperature induced fatigue and are more resilient to the harsh industrial environments.

- Sealed Components: Designs like IP65 fan guards offer water and dust protection, reducing bearing and motor wear for improved longevity.

- Maintenance: Maintenance is improved with the use of standardized parts, motors, and guards with simple removal.

- Reliability: Long-term operational reliability is enabled by suppliers who provide ongoing technical assistance and spare parts, and by partnering with such suppliers.

Purchasing a quality AC fan system will help ensure a fan and any connected components will operate together with maximum system efficiency and minimal maintenance for the fan system and connected components.

Special Functions and Custom Options

Certain specialized industrial applications will need fans with particular design or performance attributes. Many vendors will be willing to help meet the customization requirements.

- Airflow Capacity and Size: Custom sizing allows integration to existing ducts and machines.

- Phase and Voltage Options: AC fans with single or three-phase outputs.

- Additional Options: PWM and feedback control for speed, specialized blades to increase efficiency and improve noise.

- Changes for the Environment: Fans can be designed for use in extreme temperatures, with high levels of chemicals, or in high humidity.

An IP65 fan customized for environmental conditions ensures the system continues to provide optimal air circulation while facing environmental challenges, thus providing reliable and customized options for diverse industrial applications.

Choosing an AC fan for sale involves balancing an absolute plethora of factors such as performance metrics, environmental resistance, energy efficiency, and maintenance requirements. An IP65 fan is perfect for harsh industrial environments as it is impervious to dust and water ingress. Evaluating airflow, static pressure, noise, durability, and control options allows B2B buyers to select AC fans and ensure that their ventilation, cooling, and air handling systems work optimally and with reliability and safety. With the right AC fan, companies improve operational performance and lower maintenance costs, which aids in long-term industrial and commercial sustainability.